Europe's first lithium mine prospects investments to the auto industry to secure electric vehicles supply of environmentally-friendly battery materials. The company plans to deliver enough lithium to 25-gigawatt hours of battery cell supply two years from now.

The mine's operator announced during the sidelines of the CAR-Symposium in Bochum earlier this month that automakers are mulling the possibility of owning a stake on the mine because of the growing demand for batteries for electric vehicles. Prices of the battery-grade lithium hydroxide considerably vary in the market and a ton of the product sells for about $14,000

Pertti Lamberg, the CEO of Keliber Oy, said that they see the car industry is also interested to invest in mining, which hasn't ever happened before to secure their raw material source and have clear control over where their material for their batteries is coming from.

The executive declined to name the companies interested in mining. He said a fixed deal where an automaker agrees to take production for the bulk of the mine's economic lifetime is another alternative to investment. He said that it could be attractive for the auto industry especially to those who are interested in encouraging sustainability of the whole supply chain. The growing awareness of child labor in the cobalt mines in the Congo will also contribute to the flow of investment for the lithium mine.

The automakers started to be critical in the business practices of their suppliers. Recently, Volkswagen Group said that it would balance business practices with that of cost and quality when awarding the contract.

Lamberg said that a significant part of lithium would be coming from Europe and end up in European cars. He added that their materials will be traceable and also they can confirm the ecological footprint for each ton of lithium hydroxide as well.

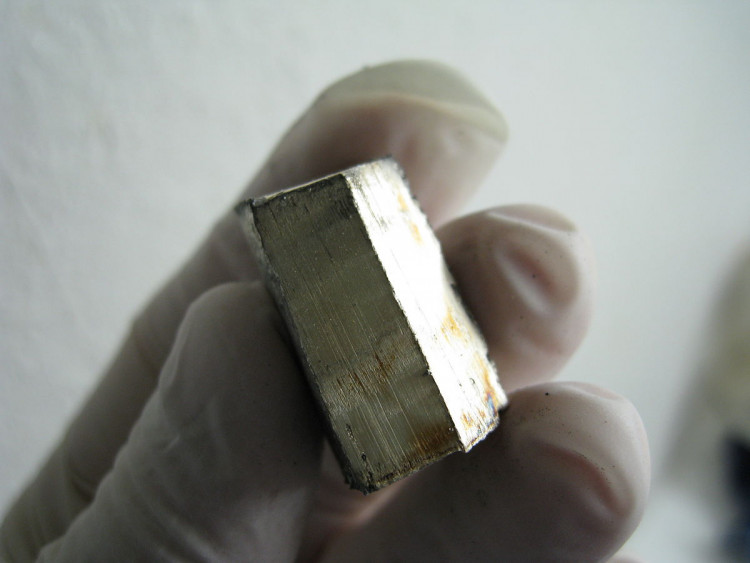

According to Lamberg, rather than sell lithium to chemical companies, Keliber will process the lithium concentrate. Keliber extracts 10 tons of battery-grade lithium hydroxide out of 100 tons of rock. The residual products of the extraction are used in local construction industries.

Lamberg said that they are using a sulfate-free process, therefore, they don't create any waste that could be harmful to the ecology. He added that the absence of chemical deposits is very rare and gives us that environmental stamp (of approval) when comparing us to other producers.

Lithium is mined in two ways depending on their chemical components. Lithium carbonate comes from salty ground waters while Lithium hydroxide is harvested from hard rock deposits.