China has stepped up its game in the application of 3D printing in a number of manufacturing sectors. Analysts are expecting the country's 3D printing industry to reach $7.68 billion next year.

According to China Daily, manufacturing sectors in the world's second-largest economy are embracing additive manufacturing, also called 3D printing. Car parts, aircraft units, and even musical instruments are being manufactured using technology.

The technology is technically new but China is among the global drivers that could lead the way in 3D printing as the year's pass. It recently unveiled an electric car printed using 3D technology.

While Beijing is already investing in advanced technology programs, Consultancy IDC predicted that the Chinese government will invest around $1.9 billion solely for 3D printing projects. In fact, China is already the third-largest market for this sector behind the United States and Western Europe respectively.

The initial National Printing Industry Development Plan unveiled in 2015 saw a series of policies developed to boost 3D technology. The Chinese Ministry of Industry and Information Technology also unveiled a second scheme late in 2017 for this cause.

President of South Asia at Stratasys, Michael Agam, said 3D printing will most likely see pivotal changes this year. He is expecting to see a breakthrough in transforming the sector from prototyping to real-life manufacturing in various industries.

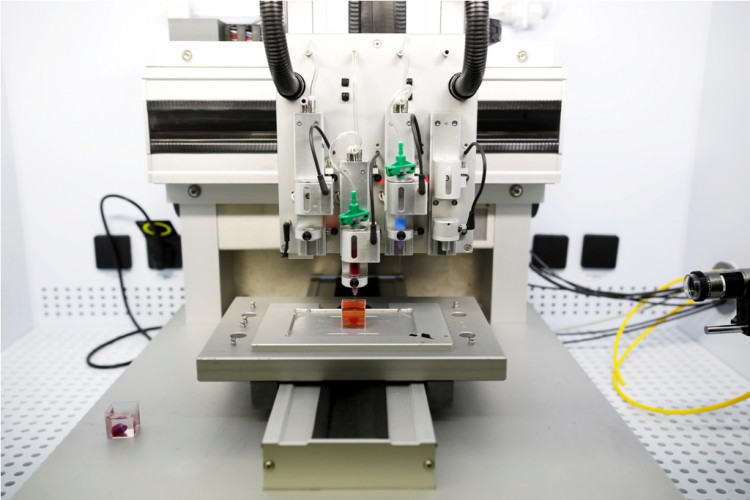

Chinese scientists have also started studying the possibility of printing electronic fibers onto textiles. Researchers are also exploring the potential of using 3D technology in printing flexible e-fibers onto clothing.

LED fibers and other electronic components are usually sewn manually into fabrics. However, a 3D printer can make the process more versatile. More importantly, the integration process is much cheaper since there will be fewer materials used.

"We hope this work will inspire others to build other types of 3D printer nozzles that can generate designs with rich compositional and structural diversity and even to integrate multiple coaxial nozzles that can product multi-functional e-textiles in one step," professor of the department of chemistry at Tsinghua University and senior author of the study, Yingying Zhang, said.

Last month, China unveiled an electrical room printed using 3D technology that has since started operations in Guangzhou. This is China's first room of its kind and was constructed in a period of 35 days. Around 30 percent of the usual construction time was reduced through the technology.

Tech experts stressed the critical role of 3D technology in China's goals of more eco-friendly and intelligent processes for manufacturing sectors. They said 3D printing is more efficient, more affordable, and reduces waste that could harm the environment.