Despite not having set a specific release date for its debut mixed reality headset, the Vision Pro, Apple plans to promote this new product in major American cities such as New York and Los Angeles in early 2024. Customers need to reserve to buy, which may make the purchase of this high-priced $3500 product more challenging.

Apple's stock experienced a small 0.8% dip, then rose 0.3%, nudging its market value back towards the historic high it hit at the end of June, a firm stand over $3 trillion.

A month ago, Wall Street Journal mentioned that following the WWDC Global Developer Conference, Apple had significantly reduced its first-year sales target for the Vision Pro to 150,000 units due to its high price, complex design, production difficulties, and constraints from major suppliers. This is far below the company's initial idea of 1 million units, let alone its ambition of achieving first-year sales of 3 million units.

Reports this week suggested that Apple's 2024 Vision Pro production may be less than 400,000 units. This is primarily due to supply constraints of "certain components," with the Silicon-based OLED micro-display presenting the biggest bottleneck.

Insiders involved in the Vision Pro production process have revealed a headache for Apple. The Silicon-based OLED micro-display required for immersive experiences near the human eye brought cost and technological challenges. This component is the most expensive part of the entire device, accounting for a whopping $700, nearly half the total manufacturing cost.

Analysts have even pointed out that high material costs and exaggerated technical difficulties mean Apple won't make much profit from its first-generation MR headsets. The company once considered selling at a loss to push the popularity of such products, but eventually set the price above $3,000, just breaking even.

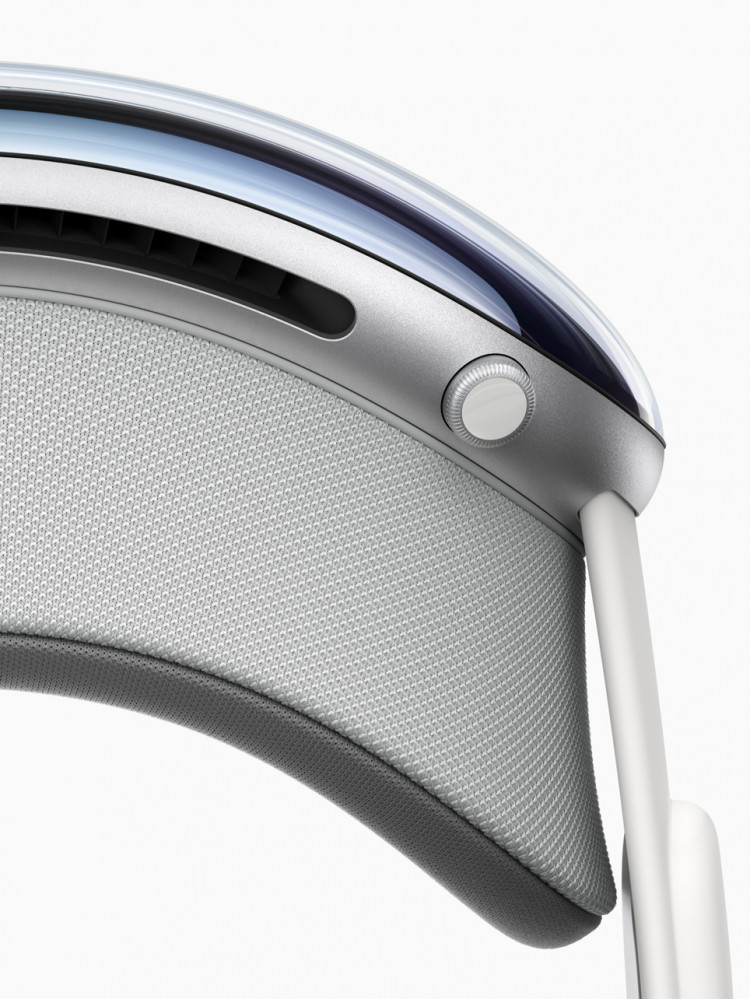

The silicon-based OLED micro-display (Micro OLED), each measuring just 1.42 inches-about the size of a postage stamp-with a resolution of 3648x3144 and a pixel density of 3391ppi. This is six times that of traditional glass-based OLED displays and exceeds the resolution of the most advanced 4K TVs per eye, with a maximum module brightness of 6000 nits.

Sony, which has been developing display technology since 2009 that laid the groundwork for later Micro OLED, manufactures the Silicon-based OLED micro-displays for Apple's first-generation Vision Pro. Silicon wafers, produced by TSMC, serve as the base for OLED deposition. Compared to traditional OLED glass or plastic bases, the silicon base helps achieve higher resolution and smaller size, with broad application prospects in mixed reality, virtual reality, and other display devices.

Recent reports have mentioned that due to the high cost of silicon wafers, the challenge of tiny dust in the manufacturing process damaging the product, and the fact that no company has begun mass production yet, the OLED micro-display that Vision Pro relies on is too costly.

Wall Street Journal previously mentioned that although the niche market characteristics will limit the sales expectations of Apple's first-generation mixed reality headsets, the actual number of Vision Pros delivered is limited by Sony's production. Sony set the upper limit of silicon-based OLED micro-display production to 900,000 units per year in mid-June, enough for no more than 450,000 Vision Pros, and declined Apple's request to expand production.

This reluctance is likely due to Sony's doubts about the future market growth prospects of mixed reality headsets, and hence their unwillingness to hastily increase the production of key components, despite analysts' belief in Sony's ability to increase production significantly.

Sony's Semiconductor Division head, Terushi Shimizu, admitted last week that the company would monitor how much demand for OLED micro-displays would increase: "We will not aggressively produce these displays, (we won't) let its production scale be the same as image sensors provided for smartphone cameras."

Insiders also revealed that, given Sony's reluctance, Korean competitors Samsung Display and LG Display may surpass Sony and become the leading suppliers of OLED micro-displays needed for future generations of Vision Pro and its subsequent products.

Samsung Display acquired American OLED micro-display manufacturer eMagin for $218 million in May this year and is currently building a factory in Korea, with trial production expected to begin next year. LG Display, who produced the external OLED display for the first-generation Vision Pro, showcased its in-house micro OLED prototype in January, and both companies could collaborate with Apple on cheaper consumer-grade mixed reality headsets.

Visionox Technology, a Chinese company established in 2016, reportedly sent multiple OLED micro-display prototypes to Apple. Apple has already dispatched staff to work with Visionox and provide feedback on the samples. However, according to two people directly involved in the process, due to ongoing concerns about component costs, no display manufacturer has yet met Apple's expectations for the technology.

Nam Sang-Uk, a researcher at the Korea Institute for Industrial Economics and Trade, pointed out that given the fierce market competition in this field, all display manufacturers are in a dilemma over whether to invest necessary resources to produce relatively niche product components:

"To improve the yield rate of Micro OLED, Samsung and LG need to invest billions of dollars. But this is not their primary task. Currently, their focus is still on OLED displays for TVs, tablets, and foldable phones, as mixed reality headsets are unlikely to sell in large quantities soon."

Previous reports stated that some supply chain insiders believe that MR headsets might be the most complicated product Apple has ever manufactured, with an expected first-year production capacity of maybe less than 500,000 units. The complexity of production is such that only one in five units is expected to be of acceptable quality in the early stages:

The curved front glass on the headset is more fragile than the flat glass on the iPhone, requiring constant adjustments by engineers. Furthermore, to fit the curved shell, Apple designed a curved motherboard. The thin frame needs to accommodate lenses, displays, a dense array of electronic components, and carbon fiber filler for reinforcement, making assembly very challenging for workers.

In the current field of OLED micro-display players, according to WitsView, the advent of Apple's Vision Pro has brought its onboard Micro OLED display technology into more people's sight. In fact, global Micro OLED display manufacturers have been cultivating this field for many years. In recent years, Chinese manufacturers have been particularly active in this field.

As mentioned earlier, Visionox Technology, which proactively contacted Apple, focuses on the R&D and production of 12-inch wafer silicon-based OLED micro-display components. On August 25 last year, DJI released the world's first consumer-level FPV flight goggles Goggles 2 using a Micro OLED screen, which used the 0.49" 1920x1080 Micro OLED micro-display developed and produced by Visionox.