Taiwan Semiconductor Manufacturing Company (TSMC), the world's largest contract chipmaker, reported a significant increase in October revenues, marking its first year-over-year growth since February. This development has sparked discussions about a potential turning point in the semiconductor industry. TSMC's stock price on the Taiwan Stock Exchange surged by more than 4.1% to 580 New Taiwan Dollars, the largest single-day gain since May.

On November 10, TSMC announced its October revenue report, showing a consolidated revenue of 243.2 billion New Taiwan Dollars (approximately 54.96 billion Yuan), a 34.8% increase from the previous month and a 15.7% increase from the same period last year. This marks the first time since February that TSMC has seen a year-over-year increase in monthly revenue.

Analysts believe this indicates a gradual recovery from the low point in the global chip market. Following this news, TSMC's U.S. stock closed up 6.35% last Friday, marking the largest single-day gain since May, although it saw a slight decline of 0.4% in pre-market trading today.

TSMC anticipates its revenue and profits for the fourth quarter of this year to continue exceeding current analyst expectations. This optimistic guidance suggests that TSMC sees a turning point in the semiconductor market, with signs of stabilization in smartphone and personal computer demand and expectations of long-term growth driven by demand in the artificial intelligence sector.

TSMC revealed that AI applications currently account for only 6% of its revenue but expects this segment to grow at an average annual rate of 50% over the next five years.

Recently, Intel and Samsung have also expressed beliefs that the worst period for the chip industry has passed. Samsung's third-quarter revenue fell 12% year-over-year, but its net profit of 5.5 trillion Korean Won significantly exceeded expectations, with a substantial narrowing of losses in its key chip business, marking Samsung's best performance this year.

Samsung anticipates a recovery in the memory chip market, expecting an increase in DRAM demand by 2024. Kim Jae-june, a high-ranking executive at Samsung's memory chip division, expressed confidence that the current recovery momentum would continue into the next year.

TSMC's CoWoS Advanced Packaging Demand Set to Surge

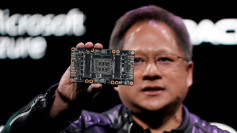

Media reports on November 13 indicated strong market demand for TSMC's CoWoS (Chip on Wafer on Substrate) packaging technology. In addition to Nvidia, which confirmed an order increase in October, heavyweight clients like Apple, AMD, Broadcom, and Marvell have also significantly increased their orders recently.

To meet the demands of these five major clients, TSMC is accelerating the expansion of its CoWoS advanced packaging capacity, with plans to increase monthly capacity by about 20% to 35,000 units next year. Industry insiders suggest that the substantial orders from TSMC's five major clients indicate a blossoming of AI applications, driving a surge in demand for AI chips.

Nvidia is currently TSMC's main customer for CoWoS advanced packaging, accounting for nearly 60% of the related capacity, including for AI chips like the H100 and A100.

Meanwhile, AMD's latest AI chip products are in the mass production stage, with the upcoming MI300 chip expected to adopt both SoIC and CoWoS advanced packaging structures.

Additionally, AMD's Xilinx has been a major customer for TSMC's CoWoS advanced packaging. With increasing AI demand, companies like Xilinx and Broadcom are also adding orders for TSMC's CoWoS capacity.

TSMC's chairman, Mark Liu, noted that the demand for increased advanced packaging capacity is not due to the high cost of advanced semiconductor processes but rather clients' needs to enhance system performance, including factors like transmission speed and reduced power consumption.

In the short term, TSMC faces the challenge of increasing capacity to meet the rapidly growing demand for AI chips. The tight capacity for CoWoS advanced packaging is impacting the shipment volume of AI chips.

As chip sizes continue to shrink, finding smarter ways to assemble different types of chips together becomes increasingly important, especially for high-demand applications like AI.

TSMC aims to double the capacity of CoWoS next year, but achieving this goal depends on the capabilities of its equipment suppliers. With CoWoS equipment lead times still around eight months, TSMC reportedly began equipment modifications in November, initiating the integration of InFO (Integrated Fan-Out) packaging technology.