India's aspirations to become a global chip-making hub are facing significant challenges, as local production struggles to keep pace with ambitious governmental targets. Despite the country's attempts to move up the global semiconductor supply chain, experts note that only 9% of India's semiconductor component consumption is currently met locally.

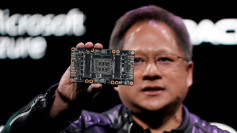

Semiconductors, critical components in a wide range of modern devices, are predominantly sourced from technologically advanced countries like Taiwan, China, the U.S., Japan, and South Korea. India's endeavor to build its indigenous semiconductor industry comes amidst a changing global landscape, accentuated by the pandemic's disruptions.

The Indian semiconductor market, valued at approximately $35 billion in 2022, is projected to reach $64 billion by 2026. Sectors like IT, industrial, mobile, and wearables are at the forefront of this growth. However, despite the increasing demand for chips, India's efforts in semiconductor manufacturing remain nascent.

In December 2021, the Indian government announced a significant scheme worth over $9 billion (Rs 76,000 crore) to attract semiconductor and display fabrication units to the country. However, two years on, this investment has seen limited utilization. The scheme has so far approved only one chip packaging unit (Micron) and seven design companies, with no approvals in the critical category of Silicon-based chip fabrication.

According to semiconductor analyst Arun Mampazhy, India is yet to make notable progress in key semiconductor categories, including Silicon-based fabrication. He notes that, globally, India is not a significant player in the semiconductor industry. By 2030, the country might achieve only about 1% of the global market share, provided two commercial Silicon fabs begin construction by 2024.

The Indian Semiconductor Mission (ISM) has been criticized for its slow progress in converting potential deals into tangible outcomes. For instance, the response to negotiations with Israeli company Tower Semiconductor has been lackluster, illustrating the ISM's challenges in advancing these initiatives.

Mampazhy points out that India lags about five decades behind in chip fabrication and related industries. While potential exists for building a robust semiconductor ecosystem, a realistic target would be to cater to 50% of the domestic and 10-15% of the global market by 2047. The focus should be on developing a strong indigenous technology ecosystem, with an emphasis on incentivizing the design ecosystem.

Counterpoint Research suggests that schemes like Make in India and the Production Linked Scheme could accelerate India's journey towards becoming a leading semiconductor component supplier. However, additional reforms are needed to boost local manufacturing and sourcing of semiconductor components, contributing to India's goal of becoming a $5-trillion economy.

In summary, while India's vision for a semiconductor hub is ambitious, it faces significant hurdles. The path ahead requires a concerted effort in developing a strong indigenous ecosystem, focusing on design-led manufacturing, and aligning with global market demands.