The race for advanced semiconductor technology intensifies as TSMC reveals its development of 1.4nm manufacturing technology, named A14, at the IEEE International Electron Devices Meeting. The company expects to mass-produce this technology between 2027 and 2028, with 2nm technology set for production in 2025.

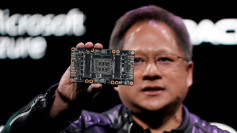

This announcement comes as TSMC has already begun pre-production of its 2nm process in early July, with Nvidia and Apple as its first clients. Currently, TSMC's most advanced mass-produced technology is the 3nm process used in the A17pro chip for the iPhone 15 Pro and Pro Max. In 2024, TSMC plans to increase the production of its 3nm chips, serving clients like Apple, Nvidia, AMD, Broadcom, MediaTek, and Qualcomm.

By 2024, major global chip foundries, including TSMC, Samsung, and Intel, are expected to enter the sub-3nm process era. The rise of large AI models is anticipated to boost demand for advanced processes. IC Insights predicts that the share of sub-10nm processes in global chip manufacturing capacity will rise significantly, from 16% in 2021 to nearly 30% in 2024.

TSMC, with a market value of approximately $536.5 billion, is the world's highest-valued semiconductor company. Advanced processes are crucial to its future prospects. TrendForce research indicates that the rise of AI chips will shift the dominance of advanced processes from mobile chips to AI applications, with high-performance computing (HPC) chips driving demand.

TSMC's production capacity is critical for mainstream AI chip manufacturers, including Nvidia, AMD, Xilinx, and Intel, which rely on TSMC's advanced processes.

While details about the 1.4nm process are scarce, comparisons between TSMC's 3nm and 2nm chips suggest significant performance improvements. However, the cost-effectiveness of advancing from 2nm to 1.4nm remains uncertain, as the investment required for equipment and resources will significantly increase.

TSMC faces challenges in maintaining its lead, as advancements in more advanced processes become increasingly difficult. The company emphasizes the need for system-level optimization to fully utilize nodes like 2nm and 1.4nm.

Competitors Samsung and Intel are also advancing their technologies. Samsung, the first to market 3nm chips, plans to introduce an enhanced 3GAP process in 2024 and achieve 2nm mass production in 2025. Intel aims to mass-produce 2nm technology in its products by 2024 and gradually apply it to its foundry business.

Despite TSMC's apparent technological lead, customers are considering alternatives. AMD and Groq have expressed interest in working with foundries other than TSMC, and Qualcomm is reportedly considering Samsung for its next-generation high-end smartphone processors.

The trend towards diversifying foundry options to mitigate supply chain risks is becoming more apparent. While TSMC remains the top choice for leading companies, others seek alternative foundries to spread risk.

TSMC Chairman Liu Deyin, addressing rumors of Samsung's aggressive pricing strategy for its 2nm technology, emphasized that customers prioritize the quality of technology.