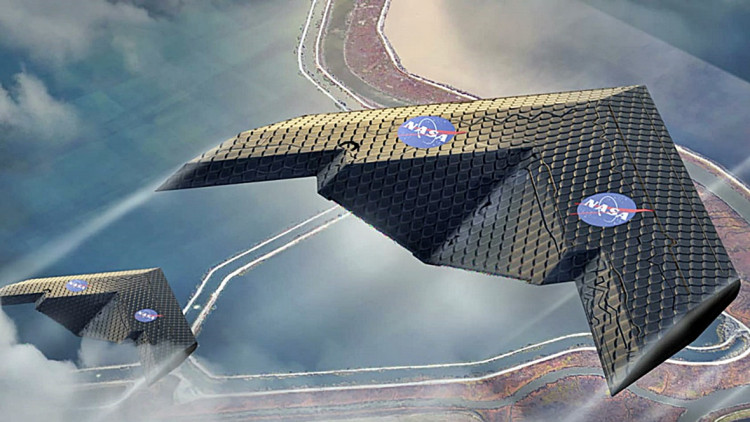

Working together, researchers from NASA and MIT have developed a revolutionary airplane wing that can change shape thereby increasing the efficiency of aircraft flight.

Measuring four meters wide, the new wing is constructed from thousands of units that fit together and function in a similar way to a bird's wing. In a traditional airplane wing, only a few parts such as flaps and ailerons can move to change the plane's direction.

In contrast, the wing designed by the MIT and NASA researchers can move in its entirety. It can adjust to the particular characteristics of each stage of flight such as takeoff and maneuvering, and can thus perform better than traditional wings.

The wing is designed to be programmable, so the wing shape will automatically morph according to the change in aerodynamic loading conditions, during different stages of flight.

The revolutionary wing is made of hundreds of small, identical pieces that contain both rigid and flexible components. This combination makes this wing lighter and more efficient than traditional airplane wings.

"We're able to gain efficiency by matching the shape to the loads at different angles of attack," said Nicholas Cramer, NASA research engineer.

The wing's parts are arranged in a lattice structure and covered in a thin, polymer material. This configuration creates a large amount of empty space. Combined, the wing's materials and structure make it as firm as a rubber-like polymer (but much less dense) and as light as an aerogel.

The wing performed better than expected during a test in a wind tunnel at NASA's Langley Research Center in Virginia, said MIT graduate student Benjamin Jenett.

The team said their design might lead to significant efficiencies in the future manufacture and maintenance of planes. Manufacturing planes such as the Boeing 787 Dreamliner or the Airbus A380 demand outsized production facilities costing hundreds of millions of dollars.

"The cost scales and the amount of infrastructure that the business needs to invest in order to implement these new designs is pretty extraordinary," said Kenneth Cheung, a research scientist from the NASA Ames Research Center.

The MIT and NASA project will try to reduce this massive cost so a plane maker can have the same sort of performance in terms of the materials, but is able to manufacture it without setting up all of the infrastructure that's required.

The new wings are made by injecting polyethylene resin into a 3D mold to create each part. These units, which will eventually be assembled by robots, allows engineers to predict exactly what shape something is going to be, just based on how many of which components they put together.

The ultralight modular structure can also be easily packed down to allow transport, which also makes it potentially the ideal for spaceflight. Taken together, these changes will result in cheaper, more flexible planes.

If the technology eventually makes its way onto commercial aircraft, it has the potential to not only change the manufacture but also the maintenance of planes, said Cheung.