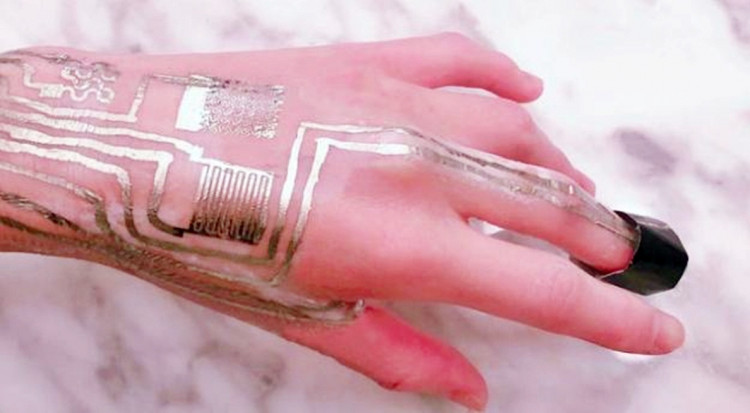

The next fashion statement might well be wearable sensors on your skin.

An international team of researchers printed sensors directly on human skin without the use of excess heat. The team from China and America developed a technique to produce precise, high-performing biometric sensors that can be painlessly attached to human skin.

The process is a special sintering technique that doesn't require heat to bond the sensors. It was developed by Penn State University department of engineering science and mechanics.

The team published its results in the journal ACS Applied Materials & Interfaces. "In this article, we report a simple yet universally applicable fabrication technique with the use of a novel sintering aid layer to enable direct printing for on-body sensors," said author Ling Zhang, a researcher for Huanyu "Larry" Cheng, the Dorothy Quiggle career development professor at Penn State.

Cheng and his colleagues previously developed flexible printed circuit boards for use in wearable sensors. On the other hand, they found printing directly on skin was hindered by the bonding process for the metallic components in the sensor.

Sintering normally requires temperatures of some 300 C to bond the sensor's silver nanoparticles together.

"The skin surface cannot withstand such a high temperature, obviously," Cheng said. "To get around this limitation, we proposed a sintering aid layer - something that would not hurt the skin and could help the material sinter together at a lower temperature."

They got around the problem by adding a nanoparticle to the mix, causing the silver particles to sinter at a lower temperature of about 100 C. This temperature, however, can still burn human skin.

Cheng said 100 C can be used to print sensors on clothing and paper, which is useful, but is still higher than a person can stand. "We changed the formula of the aid layer, changed the printing material and found that we could sinter at room temperature," he said.

The room temperature sintering aid layer consists of polyvinyl alcohol paste - also the main ingredient in cosmetic face masks - and calcium carbonate. The layer reduces printing surface roughness and allows for an ultrathin layer of metal patterns that can bend and fold while maintaining electromechanical capabilities.

When the sensor is printed, researchers use an air blower such as a hair dryer set on cool to remove the water used as a solvent in the ink.

"The outcome is profound," said Cheng. "We don't need to rely on heat."