3D printing is already a huge innovation on its own, but its impact on other industries is proof that the technology will continue to inspire great changes across other sectors.

Packaging

Earlier this year, the Nanyang Technological University and Singapore University of Technology and Design (SUTD) collaborated to present 4D printing, which is the process of objects changing back to their original 3D-printed shape.

Lead researcher at SUTD, professor Chua Chee Kai, said the reversible 4D printing technology will help in "completely changing the way we design, create, package and ship products."

While 3D printing is starting to be used in the packaging sector, 4D printing offers opportunities for the industry to reduce time-consuming processes.

Before reversible 4D printing was discovered, manual, human input was required to turn back shapes into its original 3D-printed form. With the new technology, workers can save time and improve productivity.

Medical Implants

Among the greatest contributions of 3D printing to society is its direct impact on the medical products and services industry.

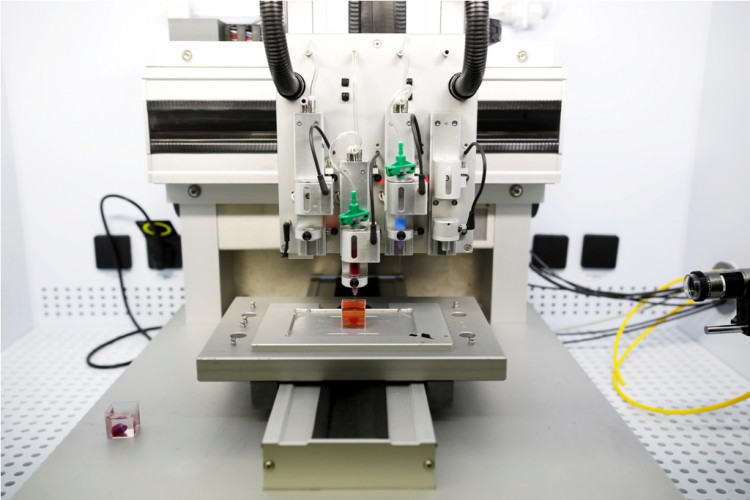

In the medical implants segment, 3D printing is being used largely to create new geometry patterns that manufacturers can use in the creation of implants that should help improve the lives of patients.

The new geometries are also tested by 3D processes to ensure their usefulness and efficiency. Furthermore, 3D printing implant geometries are fast, which accelerates manufacturing and development of in-demand medical implants.

The technology is also being used to create custom implant designs that should improve the experience of patients who need to use implants.

Auto Parts

Over the past few years, there have been news about 3D printing being used in different automotive segments, but the latest development was in auto parts.

Bridgestone developed winter tires that should work much better during the snowy season, thanks to the tire profile that the auto components company created first through 3D printing.

The winter tires feature "sipes" that change as the vehicle moves along. Chief engineer at Bridgestone, Dale Harrigle, said 3D profiling provides the engineers details on better designing tires.

Construction

Just this week, center for sustainability and construction innovation, Kamp C, said it has completed the construction of the first 3D-printed house in Germany.

The residential building was printed on-site in three weeks, the company said. The company used Europe's largest 3D concrete printer in completing the project.

The Kamp C house features two storeys, stands 8 meters tall, and has a floor area of 90-square-meters. Kamp C project manager Emiel Ascione said "production costs can be reduced" by printing houses on-site.

The latest development is expected to send ripples across the construction industry, especially with economic crises hampering construction investments and delaying projects due to added expenses.